FACILITY

Glass Fabrication

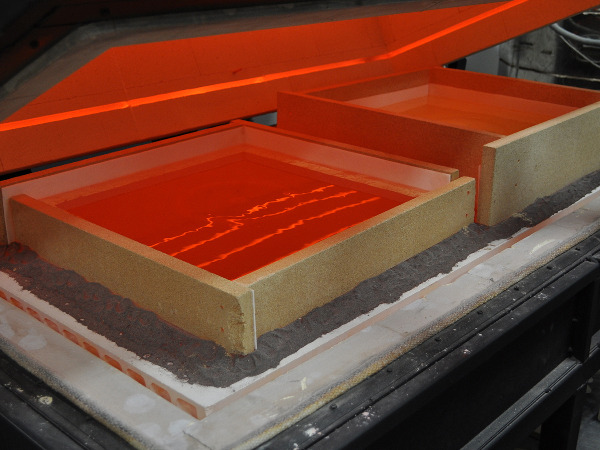

My design and production process combines research and experience with experimentation and discovery and begins when I view the glass for the first time. The sheet glass, produced by artisans in Seattle, WA, arrives at my studio in Mt. Horeb, WI in large, heavy sheets up to 48” in length. The glass is gorgeous! As I unpack the crates, I am inspired immediately by the colors and textures of each sheet of glass. In my mind, I have already begun hand-cutting, layering, and stacking the sheet glass pieces into forms and designs. Eventually, the panels of layered glass forms will be placed and fired in an industrial kiln to temperatures up to 1490°F.

Achieving the proper melt is both a science and an art form. To create a perfect melt, I must write a firing schedule that takes into account the interaction between the temperature and the form, thickness, and size of the art piece. To create kiln-formed glass, I use controlled heat to transform the layers of glass from a solid to a liquid and back into a solid again.

Glass Studio

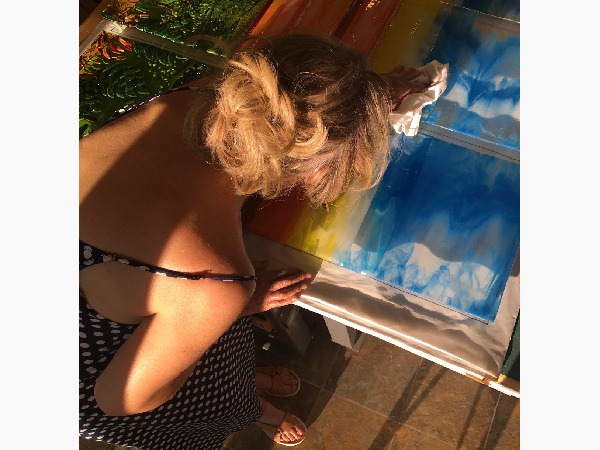

I make all of my art in my home studio which overlooks the Sugar River watershed. The region where I work and live provides me with an abundant source of beauty and inspiration. I expanded my studio in 2014 adding higher ceilings, large windows and amperage to operate a 48” kiln. Clients can arrange a studio visit to view the fused glass art process, talk to me about a commission and see some of my art. bwestfalldesign@gmail.com .

Studio Visit

Clients are invited to schedule a studio visit to view art, look at glass chip color samples, and discuss their ideas for commissioning a personalized work of art. To schedule a private consultation, please call (608.843.7515), or email bwestfalldesign@gmail.com .